Michael Edwin Alessandri

President & Founder @ Fu2ure

Inventor | Engineer | Builder

President & Founder @ Fu2ure

Inventor | Engineer | Builder

I come from a line of engineers. Detroit blood. The kind of people who can't leave anything alone, who need to know how every system works, who see a problem and immediately start tearing it apart to find the solution.

At three, I pressed my ear to the refrigerator to understand its hum. Carved branches into tools. Dismantled radios. Built my first computer from scratch at 11. That curiosity led to IT work—building networks, troubleshooting systems. Then I found my obsession: automotive performance.

I fell in love with power. Speed. The pure thrill of building machines that dominated.

By my teens, I was building high-performance engines from the ground up, tuning them with advanced electronics, creating machines that turned heads and broke records. One of my builds—a turbocharged Toyota Starlet commissioned by a client—was showcased at the largest automotive trade show in the world with such rave reviews it was later immortalized in Forza Motorsport, the premier racing video game franchise. Professional shop build to global stage to digital legend.

I launched an ECU calibration business that shattered power records. At Chrysler HQ, I worked systems engineering on flagship powertrains—SRT Hellcat, Viper, Pentastar V6. Helped develop a bill of materials process that saved the Alfa Romeo Giulia powertrain. Sent to Italy. Came back successful.

Enlisted in the U.S. Army. Trained soldiers for combat deployment to Iraq and Afghanistan at Fort Irwin's National Training Center in the Mojave Desert. Led teams under extreme conditions. Taught precision, discipline, execution under pressure.

Different missions. Same result: I lead teams that deliver.

I loved every second of it. The engineering challenges. The adrenaline. Building things that pushed limits.

But everywhere I succeeded, I saw the wreckage we were leaving behind.

The Shop Floors: Motor oil pooling in drains. Barrels of used coolant, transmission fluid, brake fluid—all toxic, all heading downstream. Exhaust emissions choking the air. Every performance gain came with a chemical cost.

The Military: Water contamination in the Mojave from fuel spills and equipment maintenance. I watched how fragile access to clean water really was—and how quickly our operations could poison it.

Chrysler and the EV Reality Check: Electric vehicles felt like the answer at first. The rush without the tailpipe guilt. Then I dug into the supply chain. Lithium mines draining aquifers in Argentina. Cobalt operations poisoning wells in Congo. Graphite refineries contaminating villages in China. Children breathing dust. Families losing their water so we could have "clean" cars.

We weren't solving the problem. We were just moving the destruction somewhere else—to communities who would never own the vehicles we were building.

The truth became undeniable: if we keep building this way, there won't be a future worth engineering for.

It wasn't abstract anymore. What world are we building? One where we poison communities to power vehicles? Where "progress" means accepting that someone, somewhere, has to sacrifice their water, their land, their health so we can have performance?

"I realized: we're on a path to destruction. And if we don't change course, we'll lose the thing I love most—performance, innovation, the pure joy of building machines that push limits. All of it, gone, if we keep poisoning the planet to fuel it."

I'm not here to lecture the automotive industry or tell people to give up what they love. I'm here to prove we can have innovation, speed, power, AND a planet worth living on. That we don't have to choose between progress and survival.

I started paying attention differently. Not to what was being built, but to what was being overlooked. Millions of tons of agricultural biomass burned in fields every year or buried in landfills. Farmers treated it as a burden.

But I saw carbon. Structure. Potential.

What if that "waste" wasn't waste at all? What if it held everything we were mining mountains to extract? Not just for batteries—for water filtration, composites, electronics, the entire clean energy ecosystem we need to keep building the things we love.

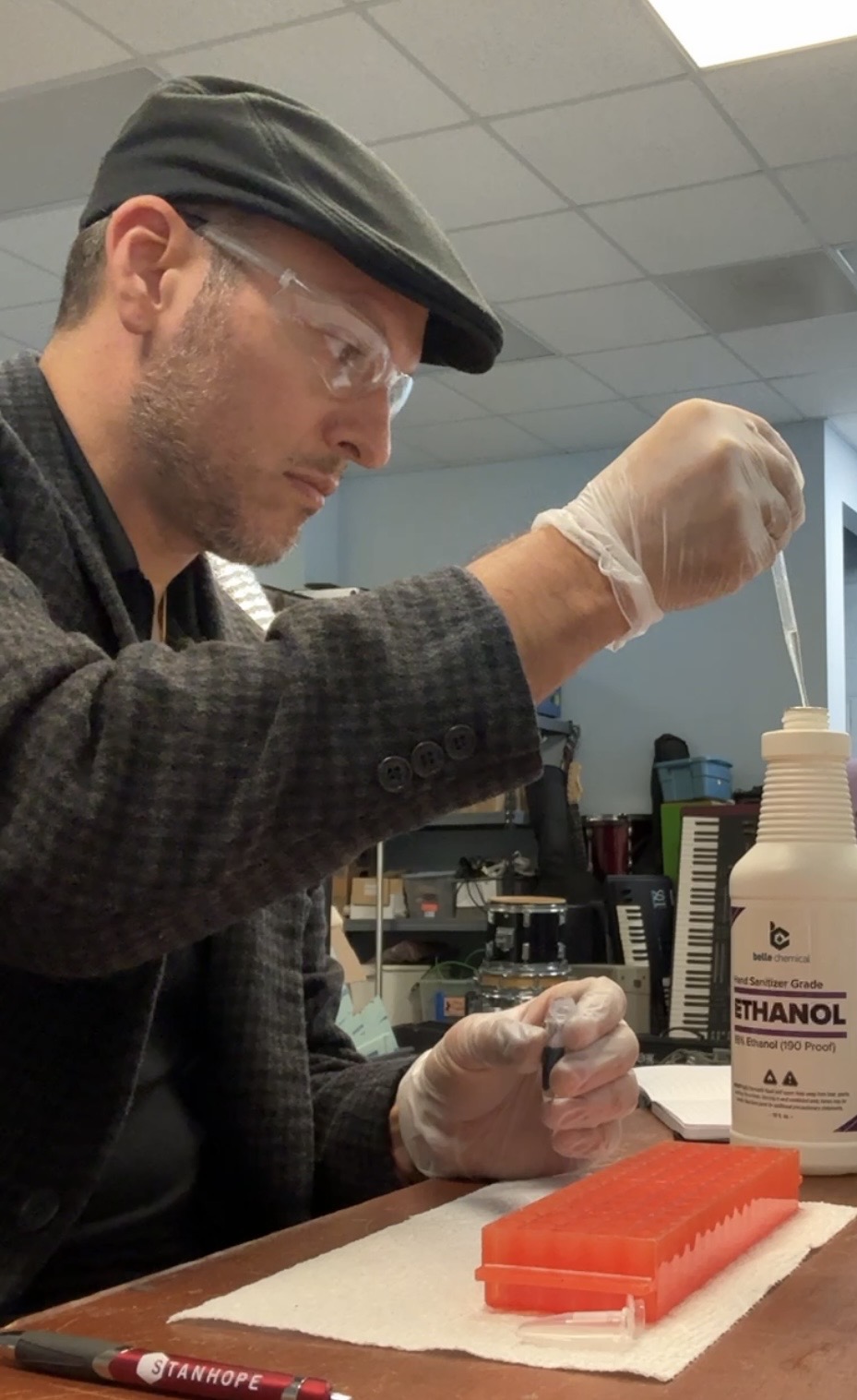

I did what I've always done: Set up a lab and started experimenting. Relentlessly. Obsessively. With access to university-level characterization and validation equipment—SEM, TEM, BET surface analysis, Raman spectroscopy—I developed Fu2ure, a patent-pending platform that transforms agricultural abundance into ultra-premium carbon materials.

Fu2ure Changes Everything:

• Zero mining—no communities poisoned for materials

• Zero hazardous waste—clean green chemistry process

• Fully circular—agricultural biomass becomes energy materials AND water purification

• Permanent carbon sequestration—climate solution with commercial value

• Seamless integration—drop-in replacement for existing manufacturing

• Performance without compromise—ultra-high surface area, hierarchical porosity

This wasn't cleverness. This was listening. Observing patterns already written into creation. The answer was here all along—we were just looking in the wrong places.

Here's what investors need to understand: We're not asking manufacturers to rebuild their operations.

Fu2ure materials match existing specifications exactly. Battery makers use the same processes. Chemical producers use the same equipment. Composite manufacturers don't retool production lines. Same performance. Clean sourcing. Zero pollution.

This isn't theoretical. This is engineering. I've spent my career making things work in the real world—from shop floors to training centers to automotive production lines. I know what it takes to integrate new technology into established systems without disrupting operations.

The market is pulling for this. Regulatory pressure is mounting—EPA tightening chemical standards, EU mandating sustainable sourcing, ESG requirements forcing supply chain transparency. Companies aren't choosing between profit and planet anymore. Regulators are making clean materials a competitive necessity.

We're positioned at the intersection of mandate and innovation.

Process byproducts return to soil as amendments—carbon-negative, not just neutral. Depleted farmland regains fertility. Marginal lands become productive again. The same process that creates energy materials also heals the earth.

This is how it should work. Abundance from what's given. Restoration built into the system. Technology that honors creation instead of exploiting it.

"I believe we're called to be stewards, not extractors. To work with what God has provided, not tear it apart for profit. Fu2ure is my answer to that calling—technology as worship, engineering as service to something greater than ourselves."

Fu2ure: 3 provisional patents. Trademark secured. This isn't just a lab project—it's a scalable platform with clear commercialization pathways built by someone who's delivered results across multiple industries.

Every skill I've acquired—military leadership, IT systems thinking, automotive fabrication, ECU calibration, powertrain engineering, business execution, and the relentless urge from the Creator to do better—has shaped me specifically for this mission.

This isn't coincidence. This is preparation meeting purpose. We're not just building better materials. We're building the future that lets us keep doing what we love—building, creating, innovating—while honoring the planet in the process.

I'm not here to lecture anyone about giving up what they love. I'm here to show there's a better way to build it.

Hands-on materials science. Direct laboratory work. Iterative process optimization.

Whether you're an investor, industry partner, or believer in restoration—there's a place for you in this mission.

Get in Touch LinkedIn Profile